Your maintainers and ground handlers power your operation by:

Positioning and Maintaining Aircraft and Equipment

Communicating and Documenting Safety Concerns

Discovering and Solving Aircraft Problems

Keeping Aircraft in the Sky Where They Belong

...But systemic issues, training deficiencies, and culture problems leave you vulnerable to seven preventable and costly mistakes. Let us help.

Program Overview

Benefits

- Safety: Proven reduction in technician-induced damage

- Efficiency: Minimized rework and aircraft downtime

- Cost Savings: Significant reduction in annual cost from Never Events and insurance claims

- Readiness: Enhanced mission reliability for your operation

- Flexibility: Available via live training, webinar, or eLearning, with licensing or ownership options

Delivery

- Series of live, in-person, half-day workshops

- Virtual webinars on your platform of choice

- Self-paced individual eLearning

- Further customization of your program as desired

The Aviation Maintenance/Ground Handling Program Proven to Reduce Injuries, Incidents, Accidents, Damage & Rework

Never Events for Aviation Maintenance/Ground Handling Value Proposition

Developed by technicians for technicians, the Aviation Maintenance Never Events® (AMNE) program is a low-cost, high-impact training solution that targets the seven preventable maintenance/ground handling “Never Events” costing the aviation industry over $40 billion annually. With a decade of refinement and proven results—training over 35,000 technicians and delivering reported “saves”—this FAA-endorsed program enhances mission readiness, ensures compliance, and slashes operational costs. By leveraging the natural problem-solving skills of maintenance personnel and ground handlers, and embedding critical awareness and teamwork tools, AMNE drives a lasting culture shift, empowering teams to declare: “Not on my team, not on my watch, not on my aircraft.”

Never Events for Aviation Maintenance/Ground Handling Program Details

Exhaustive study of industry reports and data has shown that there are seven key events that are the root of a vast majority of maintenance-related incidents and accidents in aviation (read a recent article on the topic from Global Aerospace here). We call these occurrences the “Never Events” because they are all 100% preventable. The seven Aviation Maintenance Never Events® are: Wrong Person, Wrong Part, Wrong Fluid, Improper Movement, Lost Tool or Item, Unsecured Panels, and Improper or Incomplete Inspection.

In addition to tackling the “Never Events” with professional discipline, aviation maintenance/ground handling personnel learn how to improve their Competence, Compliance, Awareness, and Teamwork. This progress also drives your organizational culture and safety programs to new levels by understanding how and why they must produce Flawless Documentation and conduct effective high-risk briefings and debriefings using the Take 5 Briefing Tool.

The entire scope and sequence of this program has been carefully designed to be scenario-based and have immediate impact on technician-caused damage. This is a program specifically put in place to change the behaviors of your aviation ground team to reflect a renewed dedication to precision and airworthiness. Finally, the strategy of this program arises from our simple eight-word performance doctrine statement:

My true best, every time, in full compliance.™

Never Events for Aviation Maintenance/Ground Handling Program Flow

A foundational strategy in this program is using “Four Tools + Documentation” to avoid Never Events: Competence to stop unintentional errors, Compliance to stop violations, Awareness of hazards/conditions that lead to Never Events, and Teamwork to catch errors and violations, plus flawless Documentation as the systemic foundation for safety. After each phase of training, every participant is awarded a program patch with a star ranking to represent their development throughout the full program, with each phase of training and star rank representing one of the focus areas.

Click through the gallery below to see details on each of the four phases and a sample of the patches awarded upon completion.

Never Events for Aviation Maintenance/Ground Handling Program Delivery Modes

To best utilize your training resources, this program is offered in three different delivery modes of your choice:

- Live in-person workshops: Each phase requires four hours of live training in sessions with up to 30 participants each. Multiple sessions may be utilized for larger organizations.

- Virtual webinars on your platform of choice: Up to 100 people can participate in each webinar session. Due to the difference between workshops and virtual training, this mode of delivery is divided into four separate sessions of 60–90 minutes each.

- Self-paced individual eLearning: Taking 6–8 hours to complete, this delivery mode features activities, videos, scenarios, and more all built into the courseware (does not include Follow-on Training Package).

Regardless of delivery mode, every participant completing any phase of this program earns four hours of FAA Inspection Authorization Refresher and Human Factors training credits and a completion certificate for that course.

Included Follow-on Training Package

Delivered at the start of training to expand on each of the four sessions with a robust communications and accountability package that keeps the new habits top of mind until they become second nature and your culture is fully aligned.

- AMNE Program Patch for participants to wear, displaying their level of advancement.

- Take 5 Briefing Tool so your team can take the most impactful part of the training right to the line and begin using it immediately.

- Gouge Guide offering deeper resources for professional development and error reduction.

- Micro-video Series that bridges the gap between training and actionable daily behaviors by delving into the Never Events and related Human Factors topics.

- Posters for each program phase used for Safety Promotion and to communicate the significance of the program to improve safety, operations, and organizational culture.

- Pre-written Monthly Email Newsletter focused on rediscovering the meaning of the material and bridging the gap between training sessions and program phases.

- Single Topic Human Factors Papers that offer quick targeting of specific errors and factors to look out for.

- Talking Points for supervisors on each of the major topic areas of the course, used to answer questions and facilitate team safety discussions.

- Implementation Guide for program managers that offers straightforward guidance on delivery and distribution, together with explanations on their use, checklists and timelines for deployment, tips/suggestions, and more.

Training Times and Scheduling

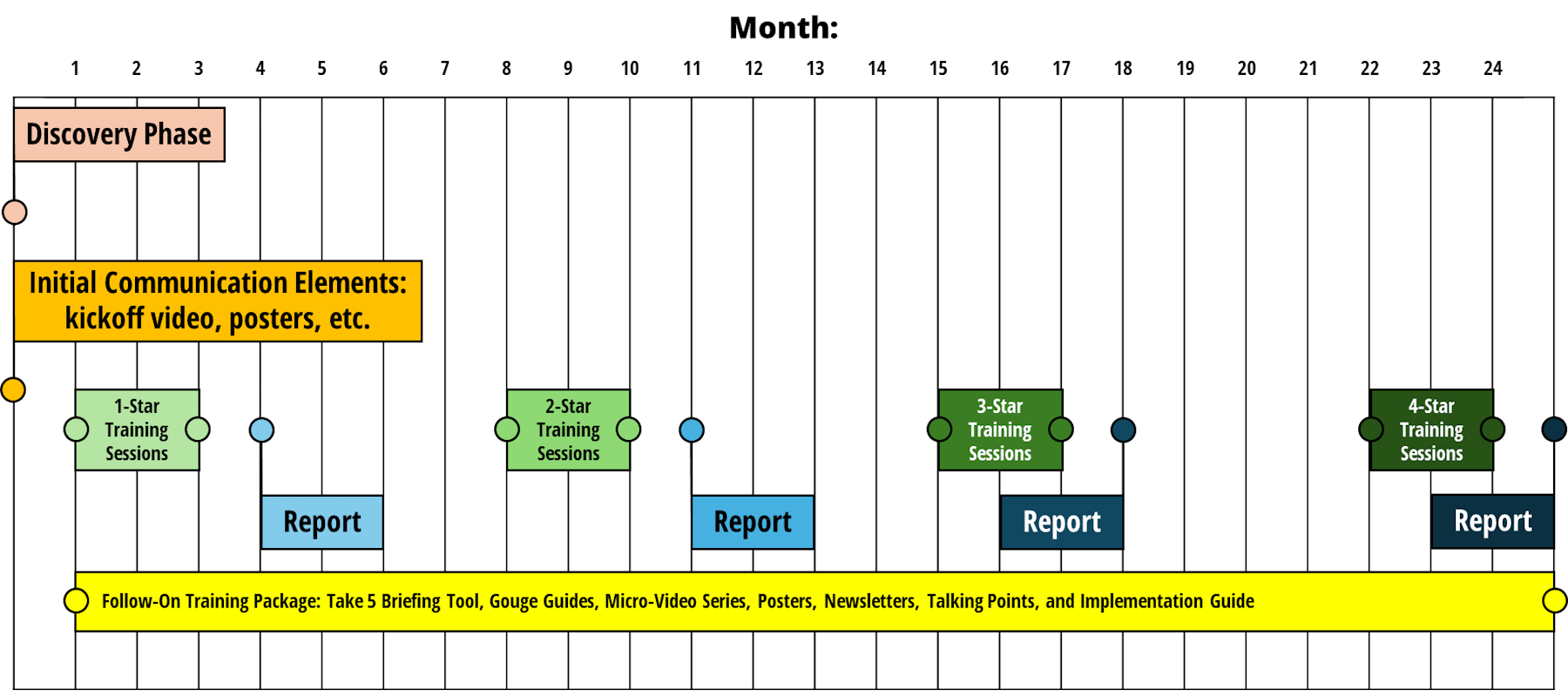

With each training session scheduled between 6-12 months apart, the program can be fully deployed in as little as two years, depending on how aggressively your team wants to pursue each milestone. After initial training is completed, every participant will also receive a 1-Star AMNE Patch to display on their uniform. For each subsequent completed phase, a new star is added. After all four phases are complete, your team members will be fully 4-Star AMNE certified and have the patch and certificates to prove it.

Example deployment schedule for the full Aviation Maintenance Never Events program (24 months):