Improve operational readiness and efficiency, eliminate costly incidents and accidents in your unique environment:

Utilize tactical briefings that improve communication and teamwork

Begin work with heightened situational awareness and sharpened focus

Empower anyone to stop work for a critical safety rebrief

Capture lessons and debrief errors immediately after task completion

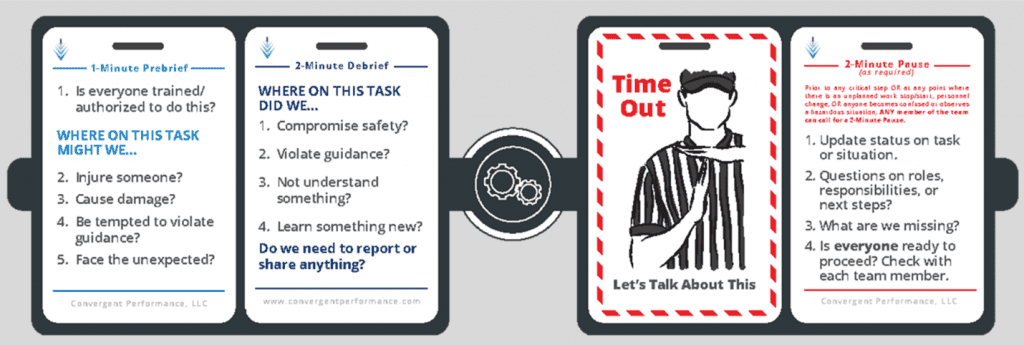

Use three short, specifically-timed communications to shed distractions and create a shared mental model across the work team. The Take 5 Briefing Program improves your self-awarenss and situational awareness and prepares the team to respond to new and emerging risk factors in real time.

Program Overview

Topics Covered

-

The 1 Minute Prebrief

-

The 2 Minute Ops Pause

-

The 2 Minute Debrief

Delivery

-

Live Webinar

-

Classroom Training

-

Custom Program

Take 5 Briefing Program: How it Works

The Take 5 Briefing Program was designed by Dr. Tony Kern to stem the tide of human error mistakes and injuries associated with high-risk work. The program is based on a concept called cognitive forcing, a means of focusing attention of individuals and teams at specific moments in time. The Take 5 briefings provide a formal mental process tool to deal with common pitfalls such as complacency, noncompliance, or “follow the leader” groupthink. Three short, specifically timed communications shed distractions and creates a shared mental model across the work team, thereby improving both self-awareness and situational awareness. While simple in form and use, it is critical that the briefings be conducted at the right moments by supervisors or team leaders who are trained in its application.

From Aviation With Love

Originally developed for aviation maintenance teams working in high-risk environments, the Take 5 program has now been utilized in a variety of settings with the same transformational results. Due to this crossover impact proven over the past three years, we are now offering this unique program across all high-risk industries.

Training for Implementation

Implementation of this simple program revolves around three critical points and requires minimal training for use.

- The first is the willingness of the workers to use the tools provided. A short 30-minute webinar or online learning program explains how and why the program works, and most importantly what is in for them as individuals.

- The second is specialized training for supervisors and team leaders who will be initially conducting the briefings. Take 5 briefings are team events, and the ability of the team lead to induce inputs are the secret to shedding distractions and creating a shared mental model. Some supervisors are naturally good at this, others must be trained to do it.

- The final key point is assessing the impact of the program. Safety and quality managers thrive on the types of employee inputs the Take 5 program produces through increased reporting and other forms of information sharing. Seeking and acting upon these important inputs from line workers is a critical piece of making this a culture-shaping and sustainable program. A short training session for these key personnel completes the circle.

Contact us to find out how we can customize this program for you.

“The Maintenance Reliability Certification is head and shoulders above any other human factors training that I have participated in. It is the deepest and most thorough research into any of the topics covered. Excellent work.”

Ben Stevens

Aircraft Maintenance Technician, Marathon Petroleum Company